What is KENMA Ⅱ Method

The KENMA II method involves attaching two semi-circular wings to a steel pipe and using a pile driver with a rotating penetration device to rotate the pipe while driving it into the ground, utilizing it as a pile.

The pile tips are manufactured under strict quality control by designated manufacturers, ensuring the supply of stable-quality pile materials. Additionally, reliable driving control ensures the foundation's bearing capacity is secured.

Features

- The unique wing shape ensures excellent penetration and workability.

- Achieved the industry's highest pullout resistance κ75, making it earthquake-resistant and difficult to pull out.

- Enables downsizing without considering the pile shaft diameter, reducing costs.

- Improved construction quality through reliable and clear driving control.

- Reduced material costs through modular pile tip design.

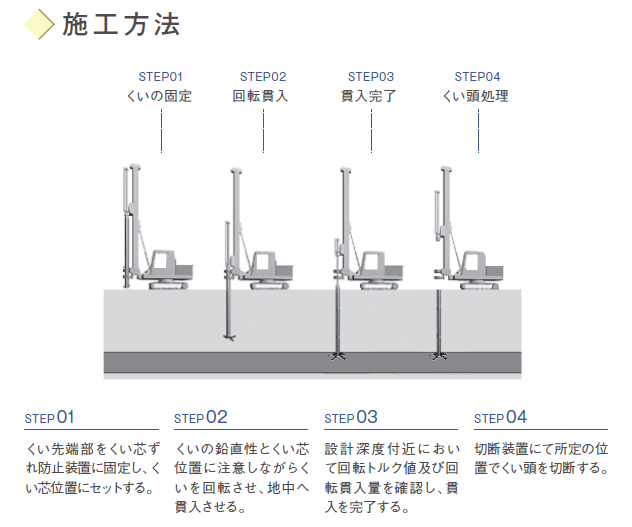

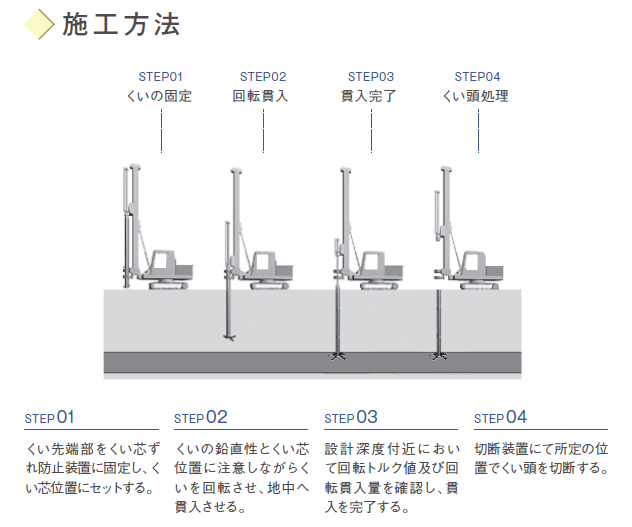

Construction Procedure

What is KENMA Ⅱ Method

The KENMA II method involves attaching two semi-circular wings to a steel pipe and using a pile driver with a rotating penetration device to rotate the pipe while driving it into the ground, utilizing it as a pile.

The pile tips are manufactured under strict quality control by designated manufacturers, ensuring the supply of stable-quality pile materials. Additionally, reliable driving control ensures the foundation's bearing capacity is secured.

Features

- The unique wing shape ensures excellent penetration and workability.

- Achieved the industry's highest pullout resistance κ75, making it earthquake-resistant and difficult to pull out.

- Enables downsizing without considering the pile shaft diameter, reducing costs.

- Improved construction quality through reliable and clear driving control.

- Reduced material costs through modular pile tip design.

Construction Procedure